Diamond mining

Despite the fact that a cut diamond is considered the most expensive stone in the entire jewelry industry, it is not a rare mineral. It is mined in many countries, but the extraction process itself is not only costly in terms of financial investments, but also dangerous and very difficult. Before diamonds appear on store shelves, their “parent” goes a very long way, sometimes decades.

Diamond deposit

Diamond is formed at very high temperature (from 1000°C) and critically high pressure (from 35 kilobars). But the main condition for its formation is the depth, reaching more than 120 kilometers underground. It is under such conditions that the densification of the crystal lattice occurs, which is, in fact, the beginning of the formation of a diamond. Then, due to magma eruptions, the deposits come out closer to the surface of the earth and are located in the so-called kimberlite pipes. But even here their location is deep under the earth's crust. The task of the seekers is, first of all, to find pipes, and only then proceed to excavations.

Mining is carried out by about 35 countries located on geologically stable continents. The most promising deposits are located in Africa, Russia, India, Brazil, and northern America.

How diamonds are mined

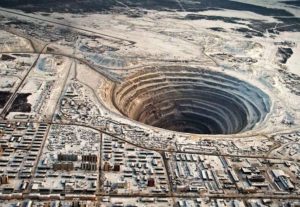

The most popular mining method is quarrying. It is dug up, holes are drilled, explosives are placed in them and blown up, revealing kimberlite pipes. The resulting rock is transported for processing to processing plants in order to detect gems. The depth of quarries is sometimes very significant - up to 500 meters or more. If kimberlite pipes were not found in the quarries, then the activities are completed and the quarry is closed, since it is impractical to look for diamonds deeper.

If kimberlite pipes are located at a depth of more than 500 m, then in this case another, more convenient method of extraction is used - mine. It is much more difficult and dangerous, but, as a rule, the most win-win. This is the method used by all diamond-producing countries.

The next, no less important stage in mining is the extraction of the gem from the ore. For this, different methods can be used:

- Fat installations. The developed rock is laid out on a table covered with a fat layer, with a stream of water. Diamonds stick to the fatty base, and water blows away the waste rock.

- X-ray. This is a manual way of detecting a mineral. Since it glows in x-rays, it is found and manually sorted from the breed.

- High density suspension. All worked out rock is moistened in a special solution. Waste rock goes to the bottom, and diamond crystals float to the surface.

There is also the easiest way to extract diamonds, which can be seen in many feature films in the adventure genre - from placers. If the kimberlite pipe is destroyed by various weather phenomena, for example, hail, rain, hurricane, then the gems, along with sand and gravel, go to the foot. We can say that in this case they simply lie on the surface of the earth. In this case, simple sifting of rocks is used to detect the mineral. But such situations, which we so often see on TV screens, are quite rare. In most cases, diamond mining is still carried out on an industrial, more serious scale.

Leave a Reply