Lost wax casting technique

Gold casting technique is one of the oldest, if not the most ancient jewelry technique. Gold, as one of the few metals, exists in its native form, i.e. in the form of a metal, not an ore, which requires great effort to obtain pure metal from it. Native gold is not always pure, most often has a small admixture of silver, copper or platinum, which, however, does not change its parameters, and when it comes to jewelry, impurities have a positive effect on the mechanical parameters of the alloy.

Lost wax method - what is it?

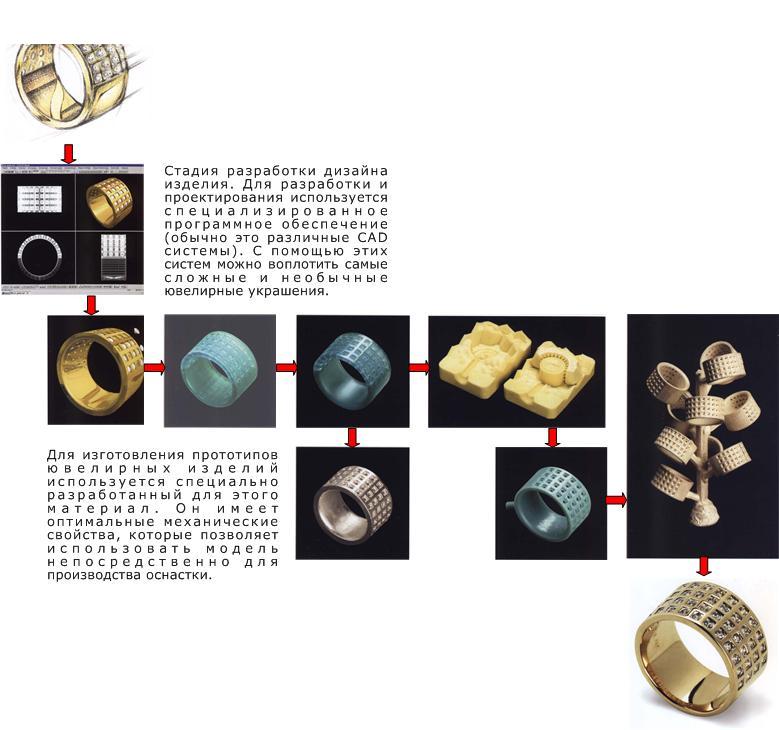

The casting technique may seem easy, simple, and cheap. But this is only an appearance, even with the current technical solutions, he likes to play pranks. One method that gives a high level of fine detail reproduction is to lost wax method. It lies in the fact that a model is being made, or rather a prototype of the object that we want to cast from wax. Next we pour it with a suitable gypsum substance to form a mold. When the mold hardens, remove the wax from it by heating it to the desired temperature. Wax flows out, a void is created in the mold in the form of a prototype.

All you have to do is fill it with molten precious metal, wait for it to cool, get rid of the mold and we have a finished, metal object that we further process. It's simple, isn't it? All the jeweler's work is focused on creating an accurate wax prototype. And this requires sculptural talent, accuracy and patience. Especially patience when the casting failed and the irretrievably lost labor invested in the manufacture of the model has to be repeated.

Leave a Reply